The cut of wood from a tree, the angle of how boards are cut when harvested, affects the wood flooring that will be made from that wood. It affects the costs of production and the final appearance of the wood flooring.

It affects wood flooring board widths, graining and the character that is revealed. It also has an impact on the floor’s performance, affecting how it responds to wetter and drier seasons, and climate regions.

4 Types of Wood Flooring Cuts

The four types of wood cuts are plain, quarter, rift and live. The cut used can depend on intended use of the wood and species of the wood, and quality of logs, and can be influenced by ways to maximize yield, emphasize grain, and avoid defects in the log.

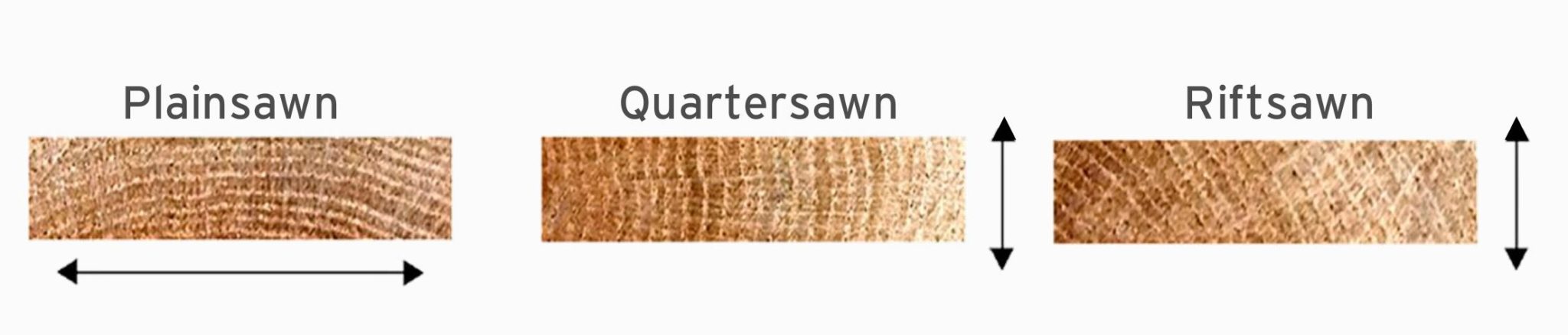

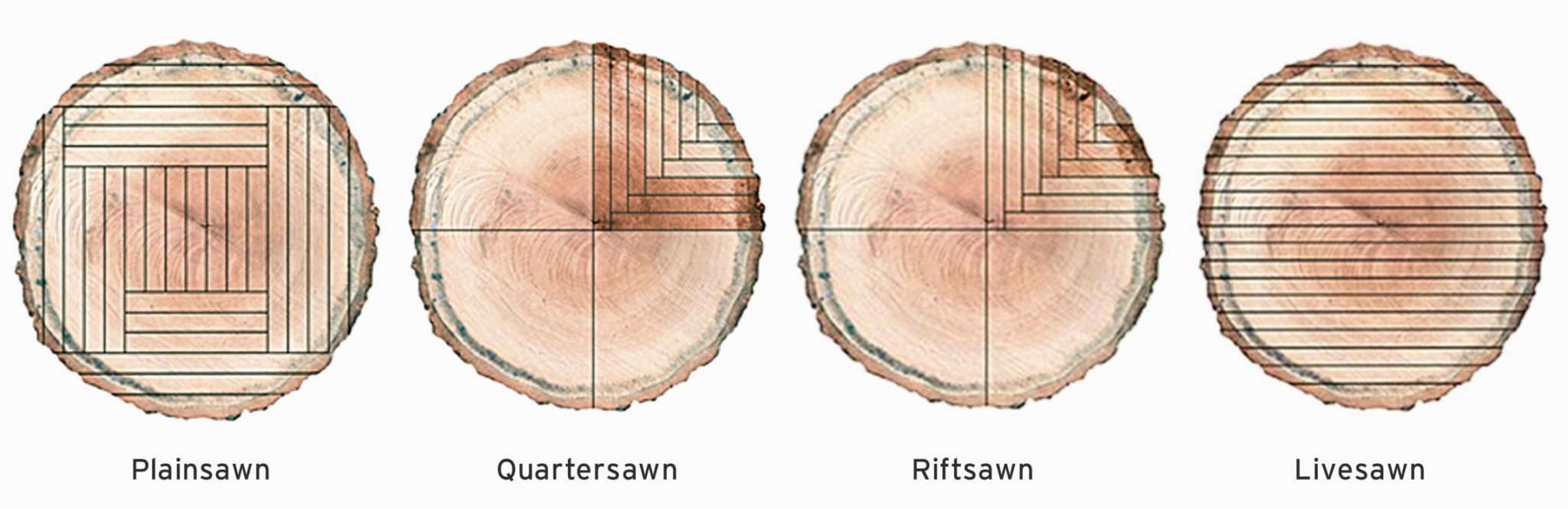

Quarter-sawn cuts are made at 45 to 90 degrees, creating somewhat narrow boards. Quarter-sawn cuts are made perpendicular to the tree’s growth rings, producing boards with vertical graining and character. It is a more expensive cut, and produces more waste from the tree because it is not an efficient cut for maximizing usable lumber.

The quarter-sawn cut of a tree produces more dimensionally stable wood. Shrinking and swelling happens more in the board’s thickness, than across its width.

Plain-sawn, or flat-sawn, is the most popular cut in flooring. Plain-sawn lumber is obtained by making a series of parallel cuts to the log followed by a series of perpendicular cuts to yield the widest width boards. This method produces boards that are wider than quarter- and rift-sawn cuts, and produces boards of varying width.

Plain-sawn cuts are made at 0 to 45 degrees and parallel to the tree’s growth rings. Plain-sawn boards tend to shrink and swell widthwise.

Rift-sawn lumber is produced by first quartering the log and then cutting from the center face and working out. The boards that come from the outside edges have 45-degree annual growth rings. These boards come from the smaller part of the quartered wedge of the tree, with the wider boards of the quartered wedge being quarter-sawn. This means rift-sawn boards are narrower than quarter- or plain-sawn.

Rift-sawn cuts are made at 30- to 60-degree angles. They highlight the vertical grain in a tree or, once the floor is installed, the grain that runs lengthwise with the floor boards.

Live-sawn wood is cut straight through the log at the center. All remaining cuts are made parallel to the initial cut. This method produces the widest boards, the least waste and combines the characteristics of plain-, quarter- and rift-sawn wood. Live-sawn wood reacts to moisture changes with shrinking or swelling in all directions.

Contact your Palo Duro sales rep to learn more about wood flooring, it’s qualities

and best uses, or call Palo Duro’s inside sales team at 303-375-0280.

Related Web Pages

The Anatomy of a Tree (+ How That Translates to Your Wood Floor)