Wood floors make the room. Any room. Every room. Maybe that’s biased.

Biased but true, for these reasons (and more):

+ Wood floors add to the home’s market value (Google it)

+ Wood floors often make the first impression when someone (you, too) enters your home

+ Wood floors will outlast other design features, serving as the interior’s foundation for 100+ years when cared for

In this post, we’re looking at wood flooring as a customizable, long-term investment, whether you intend to stay there forever or to sell your home in five years to upsize, downsize or just get a change of scenery.

5 Elements for High-End, Custom Wood Floors

Construction. Solid or engineered. Site-finished solid wood flooring gives the greatest range of options for custom results. Prefinished wood flooring, whether engineered or solid, can be manufactured with some design options described below.

Dimensions. Length, width and thickness. Solid wood flooring typically is 3/4” thick. Engineered often comes in 3/8” and 1/2” and, in some products, is available in 3/4”.

The thickness of the floor boards is less important than the wear layer thickness to your long-term options for sanding and refinishing. The wear layer is the wood above the tongue, and shows how much wood can be sanded for refinishing before the floor will have worn out its welcome.

Widths are categorized as strip or plank. Strip flooring is, by definition, less than 3”. Anything wider is considered wide-plank flooring. The popularity of wide planks has been increasing, with floors that are 5” or 7” wide becoming common. And even greater widths are available.

You can combine multiple widths in a room – a random-width pattern – by alternating boards of different widths. For example: 3”, 5” and 7” boards will create distinct differentiation. But you can choose the widths you want, for stark contrast or for nuance. They all have an impact.

Final Appearance. Finish, color and texture. On-site application of these processes to solid wood flooring can be infinitely customizable, and each is a one-of-a-kind project. Hand-scraped. Wire-brushed. Colors mixed on-site. Custom wood flooring craftsmen can make art of your floor.

Prefinished wood floors also offer these texture options, with the floors being scraped or wire-brushed during production at the factory. Colors and sheens are, of course, predetermined for prefinished products, but there are many choices on the market.

Layout. There are so many patterns, from straight lay (parallel with the walls) to straight lay at an angle (not parallel to the walls) to geometric patterns.

Parquetry is its own study in geometry as applied to wood floor layouts, using squares, triangles and diamond shapes. Marquetry involves applying intricately cut pieces to create elaborate designs in the floor.

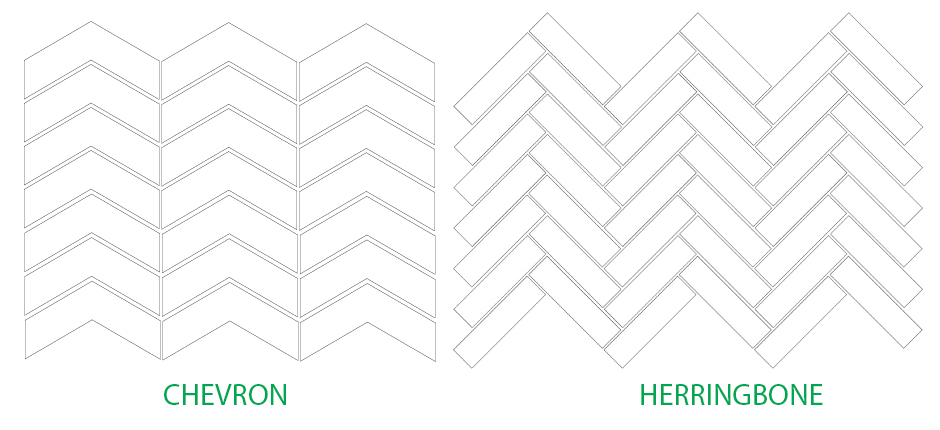

Herringbone and chevron are beautiful layouts too. They look similar at a glance. Pop quiz: Do you know which is which? See the photo comparison.

Features. Borders, inlays, medallions, mixed-materials. The custom options for these features are only limited by your imagination. High-end professionals can handcraft these custom features on-site or order elements from a manufacturer, such as a laser-cut, custom-made medallion.

Rooms can transition from tile to wood in creative and dramatic ways, even in today’s wide-open designs. They can incorporate geometric patterns that combine use of wood, stone and metal with each having their role.

The Bottom Line of Customizing Wood Floors

Customization of your floor is limited only by your imagination.

We recommend hiring a highly skilled craftsman you can verify has the right skills and knowledge to execute your intricate designs.

For leads on who those craftsmen might be in your area, use the free online “Certified Professional” tool provided by the National Wood Flooring Association.

That online search tool covers top-notch Colorado flooring pros, too, of course. But we’re happy to share our network. Call us at 303-375-0280.

Related Web Pages

The Anatomy of a Tree (+ How That Translates to Your Wood Floor)