Free Download

Grab a copy of your own to save for later!Are you planning to upgrade the flooring in your home or business, or do you already have wood floors and want to learn more about maintenance and increasing its lifespan? Well, you’ve come to the right place! With this Ultimate Guide to Hardwood Flooring, you’ll be well on your way to becoming an expert on hardwood floors.

While hardwood flooring may seem like a simple concept, there’s actually a lot more to it than many people realize. For example, you can get solid or engineered hardwood, prefinished or site-finished hardwood, and there are a large variety of wood species to choose from. Furthermore, luxury vinyl designed to look like wood (pretty convincingly so, too!) is becoming an increasingly popular alternative. It’s important to understand the similarities and differences, as well as the pros and cons of each if you want your floors to last a lifetime while looking their best.

- Before the Floor: Tree Anatomy and Characteristics

- Types of Hardwood Flooring

- The Finished Look

- Maintenance

- Pre-Installation: What to Know When Choosing Your Hardwood Floor

- Trusted Manufacturers

In this Ultimate Guide to Hardwood Flooring we’ll educate you on the basics of hardwood flooring and cover the various types available in the market, as well as manufacturers we trust, installation know-how, cleaning and maintenance tips, and much more.

Stacks of logs ready to be milled into lumber

Stacks of logs ready to be milled into lumber

Before the Floor: Tree Anatomy and Characteristics

You know what they say about the beginning – it’s a very good place to start. Wood flooring is manufactured on a massive scale, and the materials are sourced from all around the globe. There are many different options when it comes to installing it in your home or business, so it’s a good call to do some preliminary research before you make your purchase.

Tree Translations

Let’s start with the very source of hardwood flooring: the tree itself. Once you know the anatomy of wood flooring, you’ll understand a bit more about why certain species of trees, growing characteristics, and the age of the tree itself all contribute to the final look of your floors. Every tree on earth can be segmented into five different parts: the pith, heartwood, sapwood, cambrium, and the bark. Of these five parts, the pith, heartwood, and sapwood all have an impact on the appearance of the wood used for flooring. For example, throughout these parts of the tree, pores and tunnels that carried sap and nutrients will in turn produce medullary rays, which are natural streaks of color that are a very desirable design characteristic in hardwood flooring.

Choosing the Species

The species of your flooring plays another huge role in the final look and performance of your floors. Like a lot of color variation within the boards? Maybe hickory is what you should consider laying down. Are you adamant about hardwood floors but want to be sure they can hold up to your family’s active lifestyle? Maybe oak or maple is what you should lean towards because of their hardness and durability. No matter what you choose, keep in mind that each species of wood used for flooring has different appearance and performance characteristics, so be sure to read up and choose what’s right for you!

How It’s Made

When you are selecting fresh produce for your family, you’re well aware that it started as a seed, was carefully nurtured, harvested, packaged and shipped to its final destination at your local market. This same concept can be applied to the production of hardwood flooring, but rather than farm to table, it’s forest to floor. No matter where the wood is sourced, hardwood flooring is made following the same general five steps.

- Trees are cut down and delivered to a mill

- Bark is removed, and logs are cut into boards then sorted based on final use

- Boards are stacked for initial drying phase

- Boards are dried in kilns to eliminate insects or fungi and reach desired moisture content

- Lumber is cut, milled, planed, graded, and put into a controlled storage environment before being sent to its next destination

So, now that you know some of the basics of both the anatomy and logistics of hardwood flooring, why not get hip to some of the common lingo used in the industry? Before or after the installation, it’s good to know some terminology when it comes to physical appearance, species performance or, in the worst case scenarios, describing some problems that can occur with hardwood floors. Ever hear of burls or flags, or the dreaded cupping or crowning? Use this wood flooring glossary to read up on these common wood floor terms, and show that you know what you’re talking about, quite literally, from the ground on up.

|

|

Types of Hardwood Flooring

One of the very first decisions you’ll have to make has to do with the construction of the flooring. But wait – a hardwood floor is a hardwood floor, right? Well, it is right but it can also be a lot more. Hardwood floors can be constructed as either a solid or engineered piece of wood, and factors like where you live, where the floors are being installed, and what your lifestyle is like should all play into which floor you select.

- Where you live: Solid and engineered floors have different levels of stability. Stability refers to the flooring’s ability to react minimally to environmental changes. Flooring installations in more extreme climate regions, like the arid mountains or super-humid South, need to take more into consideration when choosing the construction of your flooring. (Explained: “Humidity Matters” and “Acclimation of Wood Flooring”)

- Where the floors are being installed: It’s not just the geographic environment that matters when it comes to flooring, but the environment within the building itself plays a role on what type of flooring you should install. Basements and spaces below ground are not easily regulated when it comes to temperature and moisture, so flooring that is less stable should not be installed below grade.

- Lifestyle: Wear and tear is a fact of life. Some lifestyles are more active than others, and can have bigger impacts on the flooring–think scratches, staining, and discoloration. Fixing these impacts is different for solid flooring than it is for engineered, so keep this in mind when choosing!

Solid Hardwood Flooring

Just like the name states, solid hardwood flooring typically consists of ¾” thick planks that are cut from one single piece of wood. The thickness of the solid hardwood planks is a major benefit as it can be sanded and refinished multiple times should you want a different look years down the line or the floors get damaged. If you have an active lifestyle with heavy traffic, this is a great thing to keep in mind.

Because solid flooring planks are made of one single piece of wood which can be greatly affected by environment, solid hardwood flooring should only be installed at ground level or higher, and installed using nails and/or glue.

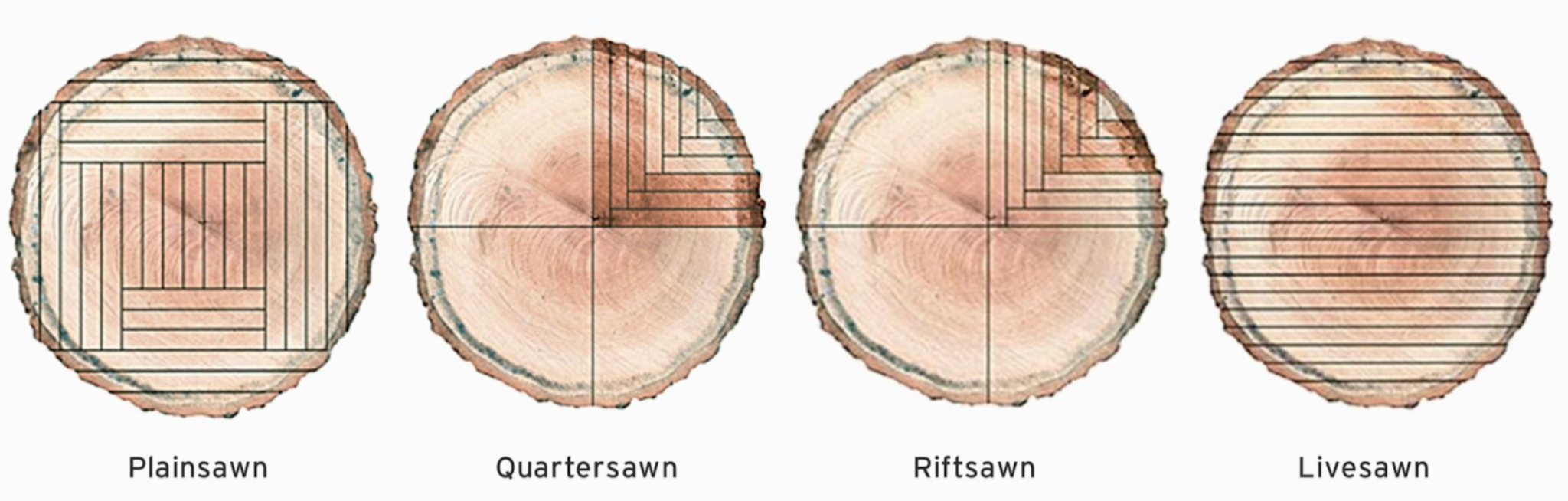

Generally, there are four types of solid wood flooring cuts:

- Quarter

- Rift

- Plain

- Live

Diagram representing the types of solid wood flooring cuts

Diagram representing the types of solid wood flooring cuts

These cuts play important roles in factors like efficient use of a felled tree, the physical look and character of the flooring, and how the boards will react to moisture in the environment. You can read more about these effects here.

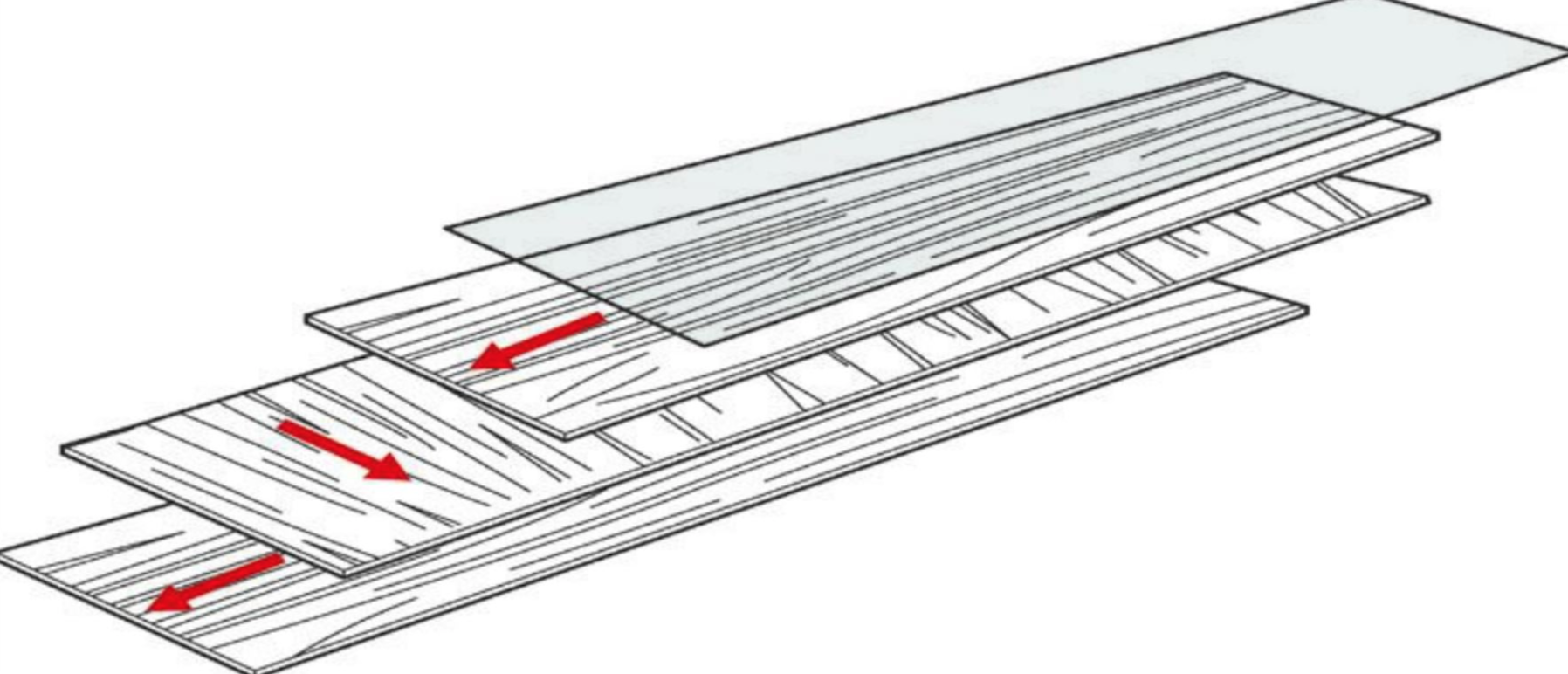

Engineered Hardwood Flooring

Wood flooring is severely affected by climate, humidity in particular. Engineered hardwood was designed to provide more stability. Engineered hardwood flooring is made up of layers, not all being wood. The top, or wear layer, and bottom layer are both made of wood, which comes in a variety of species. In most cases the core is constructed from 5 to 9 layers of plywood that crisscross in different directions, adding stability to the floor.

Cross section depicting the construction of engineered hardwood flooring

Cross section depicting the construction of engineered hardwood flooring

Engineered wood flooring is typically 3/8” thick and is installed using staples and/or glue or floating. Learn more about how it’s made and when it came into use from our post, “Engineered Wood Flooring 101.”

It is often the case that engineered hardwood is at a lower cost than solid hardwood. However, as with anything, the price will vary. Plank size, lumber cost, in addition to the quality and cost of glues plus installation, will be determining factors.

The Finished Look

As the largest piece of furniture in a house, a floor can really set the tone for a space’s entire aesthetic. Color and texture of floors play a huge role in any room’s finished look, and when it comes to wood flooring, the design potential is virtually unlimited. When installing a new wood floor, buyers have two options when it comes to the look: they can get prefinished floors or they can have their installer do a custom stain and finish application, commonly called site-finished floors.

There are plenty of benefits to both prefinished and site-finished flooring, read below to learn more.

|

|

Prefinished Hardwood Flooring

Prefinished hardwood floors are sanded and finished during the manufacturing process. The wood planks are packaged and delivered ready for use as soon as the flooring is installed.

Convenience. For any floor installation project, all the furniture and appliances need to be moved out of the way. The family of the home or tenants of the building, including pets, will live with disruption during the project. It’s a short-term pain that depends on the size of the project, but prefinished hardwood flooring lessens the inconvenience.

Design Selection. With prefinished wood flooring, it’s easy to take a short board shopping with you to compare colors, graining and texture against other design elements you’re considering (e.g. paint colors, rugs, furniture styles and colors).

Time savings. Prefinished floor installation can be completed in less time than a floor that also requires on-site sanding and finishing. Prefinished flooring is ready to use as soon as it’s installed. You’ll be capable of putting the fridge and furniture back in place and keeping your busy schedule on track.

Minimal dust and odor. Even though dust from sanding can be heavily reduced on-site these days, nothing minimizes dust from a work zone like having that part of the process happen elsewhere. Floor finish, like wall paint, has an odor. Prefinished flooring means the finish is applied, dried and cured at the factory. No finish in the home or business, no finish odor.

Durability. Factory-finished wood flooring is finished with products that provide durability. But there can be a trade-off. If the finish includes aluminum oxide, is ceramic-fortified, or uses nano-technologies, it can make future sanding and refinishing projects more difficult.

|

|

| Solid wirebrushed hickory floors from Muscanell Millworks | |

Site-Finished Hardwood Flooring

Site-finished floors are where the potential for customization and the skill of your craftsmen really have the ability to shine. Although these are more time-intensive than prefinished, they can result in one-of-a-kind floors that are sure to make a statement.

Consistency. While unfinished wood flooring naturally will have slight over- and under-wood when installed (the uneven edges and ends from board to board), quality sanding work will flatten and smooth those variations. Prefinished, or factory-finished, wood flooring removes them by beveling the edges and ends.

Those bevels create grooves in your prefinished floor. Site-finished wood floors have a flatter, more consistent surface without a bevel – unless you customize them. (Exception described below.)

Site-finished wood flooring also enables the most consistent finish for cleanliness and protecting against moisture from the top side of the floor. Where prefinished wood floor boards are individually coated, the beveled grooves can collect dirt and debris, and there inherently is space between boards that is not sealed. With site-finished floors, the finish is rolled across the boards, which seals those hairline spaces with uniform protection that covers the whole floor.

Creativity. Customization can be maximized with unfinished wood flooring. The limitations are only your imagination, the skills of the contractor you hire, and, of course, budget.

Customizations are made with unfinished wood, so they require sanding and finishing on site. That rules them out for prefinished flooring projects. With site-finished floors, you can add inlays of wood, metal and stone. You can also add special borders and ornate medallions or create texture by hand scraping or wire brushing the wood. The options for colors are infinite.

And, contrary to what was said in the section above about there not being bevels with site-finished hardwood floors, if you want the edges of your site-finished floor to have beveled or hand-scraped scalloped edges and ends, a craftsman can make that happen.

Choices. You can choose colors that fit your overall interior design. Do you have wall paint, rugs, artwork or furniture upholstery samples you would like the flooring to complement? A craftsman can mix and match as needed to produce a wood floor stain color that is unique to your home.

You also have a choice of wood floor finishes and sheens with site-finished flooring. These options can be tailored to your needs and overall desired appearance, such as a natural finish that enhances the look of the wood’s grain and character. From UV finishes to oil finishes, you’ll find something that’s right for you and your lifestyle.

Matching. If you already have wood flooring in your home or business and need to replace some of it, or if you want to install wood flooring to match in an adjacent space, site-finished wood offers your best chance to match color just right.

It’s nearly impossible to match colors of prefinished wood flooring with existing wood flooring. Even if you can buy the same product as what is already installed in your home or business, the flooring will have been produced as part of a different batch at a different time. It’s reasonable to expect slight variations between the “then” and “now” batches.

Finish and stain colors can be matched on site to the existing floor.

Maintenance

Whether it’s installed in just one room or throughout the whole space, hardwood floors tend to be a hefty investment. Therefore, it’s wise to know how to best upkeep and maintain your floors to keep them looking their best for years on end.

There are quite a few do’s and don’ts when it comes to keeping your hardwood floors in top shape. They don’t have the same maintenance routine as tile, laminate, or carpet even though you can use some of the same cleaning tools. For instance:

- You CAN use your vacuum on hardwood, but you SHOULDN’T use one with a beater bar (the fluffer mechanism that pulls up matted carpet). It’ll wear down the surface of your finish, potentially scratching up your floors.

- You CAN use a mop on hardwood, but it SHOULDN’T be sopping wet. Damp is okay, but if there’s too much water you can damage the floor boards or even the subfloor below.

There are other issues that can come up with hardwood floors, and one of the most common examples is squeaks. Short of feeling like you’re living in a haunted house, squeaky floors can be a source of great annoyance. This can happen if your floors are nailed down and they’re rubbing up and down on the subfloor, or if moisture has gotten into the boards causing gaps to occur, again leading to movement against the nails. Thankfully, depending on the source of the noise, there are solutions! Now, depending on your level of comfort you can handle these fixes yourself. They can range from applying adhesives, buying squeak-elimination kits from the hardware store, or even installing shims. To see how to take matters into your own hands, be sure to read our post on how to fix a squeaky floor.

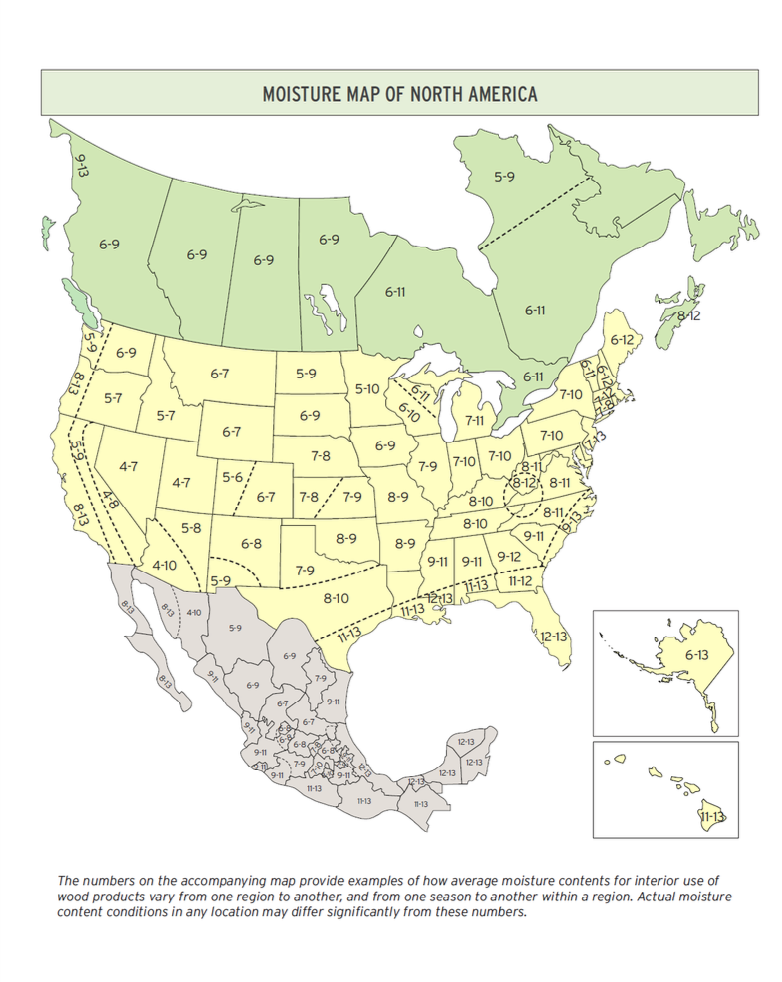

One of the most important things to know about hardwood floors is the relationship between water and wood. They’re hygroscopic, meaning they expand and contract based on the amount of moisture in them. That moisture could come from spills, steam from a shower, or even boiling a pot of water.

The key thing to remember is that humidity matters, so if you’re on top of the different factors that could cause either too little or too much moisture in the environment then you’re well on your way to keeping your floors as beautiful as they were on day one.

Pre-Installation: What to Know When Choosing Your Hardwood Floor

Forewarned is forearmed, and it’s no different when it comes to hardwood flooring. Before you even start shopping for the perfect floor, you should ask yourself – is your house hardwood ready? Hardwood isn’t a set it and forget it type of flooring. It isn’t complicated to maintain by any means, but there are some basics to know before you have it installed in your home or business.

One of the first things to take into account is your geographic location. The general climate of where you live can actually impact the performance of your floors due to the temperature you keep inside your home or business. You’ll want to talk to your installer about species that will be able to withstand the environment.

If you live in an area where it can get pretty chilly, determine what time of heating system you have. Do you have forced air or radiant heat? Forced air systems typically use furnaces or boilers and push air from one source throughout the building, and radiant heat directly warms a surface using electricity or hot water which then rises throughout the room. While forced air can sometimes have an impact on floor performance, you’ll definitely have more to consider if you have radiant heat. By reading our post on radiant heat, you’ll learn things like:

If you live in an area where it can get pretty chilly, determine what time of heating system you have. Do you have forced air or radiant heat? Forced air systems typically use furnaces or boilers and push air from one source throughout the building, and radiant heat directly warms a surface using electricity or hot water which then rises throughout the room. While forced air can sometimes have an impact on floor performance, you’ll definitely have more to consider if you have radiant heat. By reading our post on radiant heat, you’ll learn things like:

- Types of radiant heat

- How radiant heat works with wood flooring

- What to know about installing wood flooring over radiant heat

- Tips based on type of flooring (e.g. engineered vs. solid, floating vs. nail- or glue-down)

Next, it’s important to know a bit about acclimation. Once your flooring is delivered to the installation site, it needs some time to adjust and settle in to its surroundings. Basically, the moisture level in the flooring should balance with its new environment. The time it needs to acclimate depends on a couple factors:

- Manufacturer’s instructions (Warranties depend on following them)

- Wood species to be installed (Tropical or domestic?)

- Moisture content (What’s right for your region?)

- Home environment (Consistent temperature and relative humidity)

Another thing to keep in mind is what you’re putting the floor on top of. Is the subfloor wood or concrete? Factors like flatness and moisture play a role in the success of your floors for both types, and your installer should be on top of checking the circumstances are right before the first board goes down.

Choosing the right partner to install your floors will take a lot of the worry out of putting hardwood floors in your home, and they’ll likely have the answers to most of the questions you have. We always suggest finding an NWFA Certified Professional to perform the installation of your floor–they go through rigorous testing and continuing education to get that title, so if they have it, you know they’ve earned it.

Hardwood floors are not only gorgeous, but they’re durable, long-lasting, less likely to spread allergens, and even increase the value of your home or office space. So whether you’re putting them in for you and your family to enjoy or to make an investment on a future sale, with a little prep and knowledge, hardwood flooring is the perfect addition.

Trusted Manufacturers

When it comes to choosing a product to use, recommendations from friends and family are the most trusted. Well, we at Palo Duro Hardwoods like to consider ourselves one of your best friends when it comes to all things wood flooring, so we put together a list of some trusted manufacturers that we’ve built relationships with over the 30-plus years we’ve been in business. Included are companies that make both prefinished and unfinished flooring, solid and engineered. These are floors that we put in our own homes and business, so we feel confident recommending them to you for yours. Call us today to ask for suggestions on which product is right for you.